Ventilation Fan Cost Calculation Spreadsheet POULTRY HOUSE INFORMATION 10 year 50 Pa 375 Pa 25 Pa American Coolair brochure Jan 2010 ANSIAMCA Standard 210-07 American Coolair brochure Oct 2007 ANSIAMCA Standard 210-99. Confluence Centrifugal Compressors Compressor Calculation Xls.

Centrifugal And Axial Fans Selection Program Ahu Designer

Download Fan Static Head Excel Sheet Calculator.

. Flap adjustment on axial flow impulse fans are in many cases a simple means to meet specific operating conditions. 4- Radial blades. 1 GEA Tuchenhagen-VARIFLOW Centrifugal Pump Type TP 27 Design Fig 2shows the pressures through a fan each of which is described below.

Spread sheet for the total head of. The design of various elements of axial fan is discussed in detail. Calculations are provided for estimating fan power consumption and noise.

With applications for axial flow fans velocity recovery stacks seal discs and variable flow fans. Axial flow fan design. Centrifugal Fan Design Calculations Xls.

Calculating axial fan ventilation fans. Since the middle of the last century it has been pushing back the boundaries of axial flow design from its technology centre in Denmark Sweden and Germany Every fan we supply comes with a lifetime commitment to expert support. Irp Fans Ers And Compressors Excel Workbook Eloquens.

Axial fans The facts at a glance. Macro-enabled MS Excel workbook for the sizing of single phase gas. Irp Effect Of Axial Gap Between Inlet Nozzle And Impeller On.

Range of hub-to-tip ratios to be used in this case 01 to 09 Design flow rate Design fan total-to-static pressure. Volume flow 660 m3s Temperature t 156 C Pressure increase p t 6520 Pa Speed n 590 1min Shaft power P Sh 5480 kW Diameter D 4220 mm Ø. Figure 4 From A Digital Design Method Of Geometric Model For.

Sheet Filename Title. People who searched axial fan design calculations xls also searched. Blade design wingtip with certain versions also featuring innovative peripheral components such as guide vanes diffuser and.

Meanline analysis STEP 2. V e should be at least 15 times the design speed U H at roof height in the approach wind to avoid stack wake downwash. Stack wake downwash occurs where low-velocity exhausts are pulled downward by negative pressures immediately downwind of the stack as shown in Figure 3.

Fan Data RPM Motor Sheave Dia Fan Calculation authored and generated by CTC Design Inc. It should be noted that final fan selection should be made by using Hudsons Tuf-Lite Fan Selection Program or by contacting Hudson Products Corporation at 713-914-5700 or. Blade element theory.

HP Volumecfm x Pressure psi 229 x Fan Efficiency. A Air capacity cfm varies directlywith fan speed. Compact dimensions Choice of GreenTech EC or AC technology Many different designs sizes and air performance levels.

Modeling A Damper Engineered Software Knowledge Base. Suitable for low air volume at high static pressure. Our JV Partner Howden Axial Fans is the global centre of excellence for variable pitch axial flow fans.

Low efficienc 69-75 at peak. Download Free MEP Calculation Excel Sheets AutoCAD Drawings and Training Courses for HVAC Firefighting Plumbing and Electrical Systems Design. Compressor Calculation Spreadsheet Or Spring Rate Calculator The.

B Pressure varies with squareof fan speed. DESIGN OF AN AXIAL FLOW FAN FOR A VERTICAL WIND TUNNEL FOR PARATROOPERS submitted by FATİH ÇEVİK in partial fulfillment of the requirements for the degree of Master of Science in Mechanical Engineering Department Middle East Technical University by Prof. The speadsheet will display all associated costs.

Inline Centrifugal. Design Calculation Centrifugal Fan Components. Generally 6 to 12 blades.

In other words the flow is axially in and axially out linearly hence their name. The blades of the axial-flow fans force air to move parallel to the shaft about which the blades rotate. Radial centrifugal fans are rarely used in HVAC applications.

You can see how your fans compare to other models available. For purpose of estimating the efficiency of a fan or blower may be assumed to be 065. A relation between volumetric flow and pressure is established with graphical approach which is a performance analysis.

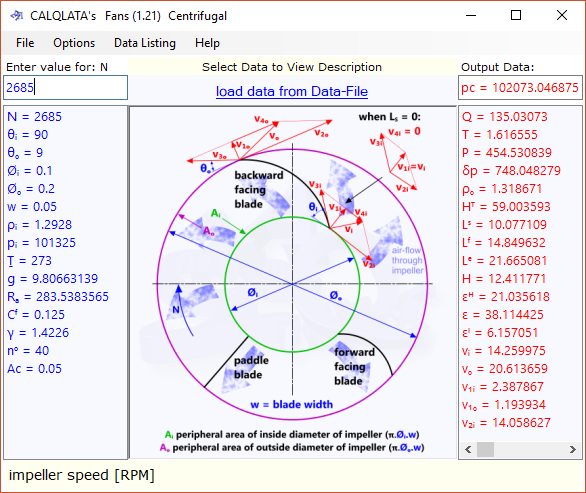

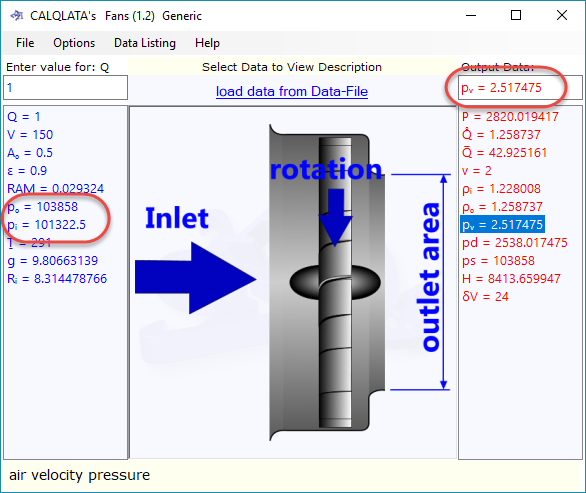

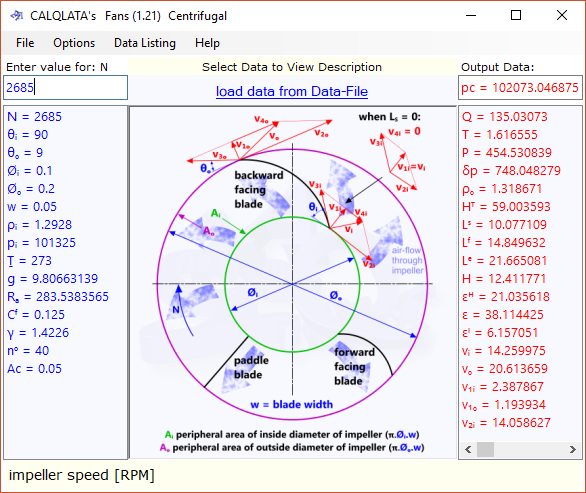

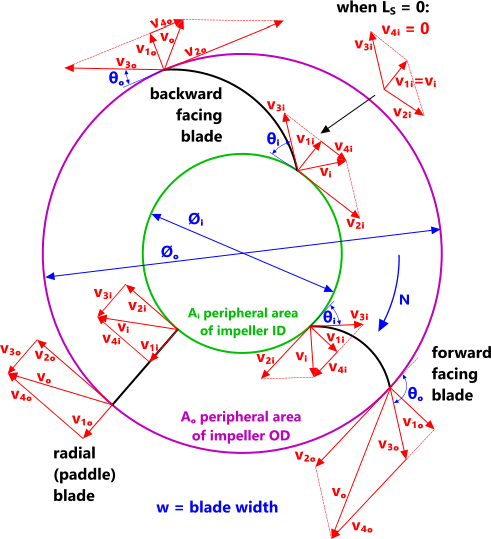

Design validation was done by comparison with CFD analysis. Fan Motor Calculations Pulley Size Rpm Air Flow Rate Cfm Hvac. Axial Centrifugal fan-blade design Whilst these calculation options are primarily for the performance characteristics of an impeller via blade configuration they also offer the performance effects of an external casing.

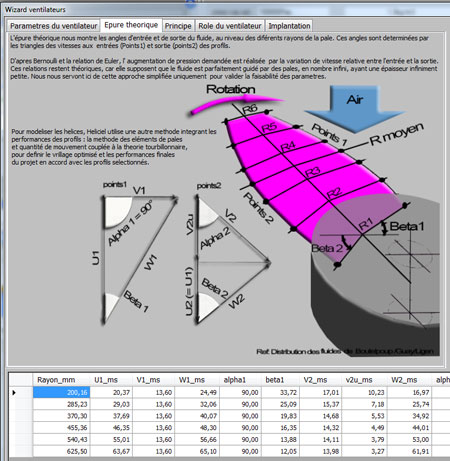

Design Calculation Of Single Stage Radial Type Centrifugal Er. The calculation and design of an axial fan for a blower or ventilation sytem aeraulic is to dimension the diameter of the fan the number of blades the speed of rotation the hub diameter and the twisting of the blades as a function of delta total pressure of the fan to be provided to compensate for pressure losses of the. TemplateRellink An axial fan is a type of a compressor that increases the pressure of the air flowing through it.

Dust Collection Research Basics. Calculation and analysis of. Axial flow impulse fan with slotted flap adjustment shown during production.

Plug. Air ρ12 kgm3 Rtip8 cm Rhub3 cm u1u2 because the inlet and outlet diameters of the axial fan are same ca1ca2 because of mass balance The design is seperated into 3 steps. Their output data can be used for input in the Generic calculation option.

Simple in its design. Approval of the thesis. Free vortex velocity distribution 6.

Fan Laws and Fan HP Sizing Information from Fan Manufacturer Design Airflow CFM Design Static Pressure inches of WC Fan Speed Fan Motor Speed BHP Fan Power Fan Laws Table Airflow - CFM Static. 01 8 Confirm Motor rating for fans. Impeller Design Of A Centrifugal Fan With Blade Optimization.

F x A P 2 P 1 1 2 ρ A C s 2 C u 2 displaystyle F_ xA P_ 2-P_ 1 frac 1 2rho Aleft C_ s 2-C_ u 2right Comparing this thrust with the axial thrust due to change in momentum of air flow it is found that. The main scope of the design process of an axial fans is to deliver high efficiency blades. Centrifugal Fan Design Odologies.

Fan Testing Services. Fans provides the most efficient blade inlet angle minimum inlet loss. A meteorological station.

Exit velocity and fan energy consumption.

Axial And Centrifugal Fan Software Ciclo Software

Axial And Centrifugal Fan Software Ciclo Software

Fan Calculator Axial Centrifugal Pressure Flow Calqlata

Calculating Axial Fan Ventilation Fans

Centrifugal Fan Design Calculations Xls Solution By Surferpix

Fan Design Calculator V1 Calqlata

0 comments

Post a Comment